Since the

increased use of manure storage facilities in agriculture there

have been numerous instances where a farmer, family member,

or employee has asphyxiated or succumbed to toxic gases from

the storage. Cases have been documented where several individuals

have died while attempting to rescue a coworker or family member

from an underground pit or a spreader tank.

What toxic gases are present around such storage facilities?

The four main gases produced from decomposing manure are Hydrogen

Sulfide, Methane, Ammonia, and Carbon Dioxide. In high concentrations,

each of these gases may pose a health threat to humans and livestock.

In animal housing facilities, where the manure pit is often

located below the facility floor, manure gases are generally

detectable in low concentrations throughout the year. When pits

are agitated for pumping, some or all of these gases are rapidly

released from the manure and may reach toxic levels or displace

oxygen, increasing the risk to humans and livestock.

THE PRIMARY

HAZARDS OF THESE GASES ARE:

Toxic or poisonous reactions in people or animals, oxygen depletion

which can result in asphyxiation and explosions that can occur

when oxygen mixes with the gases such as methane.

CHARACTERISTICS

OF HYDROGEN SULFIDE (H2S)

Hydrogen sulfide is considered the most dangerous of the byproducts

of manure decomposition. It has a, distinct rotten egg smell

and is heavier than air. After breathing this gas for a short

time, your sense of smell becomes fatigued and you can no longer

detect an odor.

At low concentrations H2S irritates the eyes and respiratory

tract while at moderate levels exposure causes headache, nausea,

and dizziness. At high concentrations H2S paralyzes the nerve

cells of the nose to the point where the person can no longer

smell the gas. Both carbon dioxide and hydrogen sulfide are

heavier than air, and will tend to settle to the lower areas

of the storage facility and remain in high concentrations even

after ventilation.

CHARACTERISTICS

OF AMMONIA (NH3)

Ammonia has a distinct, sharp, penetrating odor detectable at

very low concentrations. It is heavier than air, and at moderate

levels of concentration, it can irritate the eyes and respiratory

tract. At high concentrations it can cause ulceration to the

eyes and severe irritation to the respiratory tract. . Flushing

irritated skin or eyes with water is the best first-aid treatment

CHARACTERISTICS

OF CARBON DIOXIDE (CO2)

Carbon Dioxide is heavier than air and difficult to detect.

It replaces Oxygen in air and acts as an asphyxiate. At moderate

concentrations it causes shortness of breath and dizziness.

It is a major contributing factor to animal deaths by asphyxiation

in confinement buildings with faulty ventilation. In addition

to manure decomposition, carbon dioxide is also a byproduct

of livestock respiration.

CHARACTERISTICS

OF METHANE (CH4)

Methane is odorless and lighter than air, so it tends to accumulate

at the top of manure pits. It is considered an asphyxiate at

extremely high concentrations. The main hazard is its flammable,

explosive nature. Methane is extremely difficult to detect without

gas detection instruments because it is odorless, but it should

be anticipated as being present in all manure storage areas.

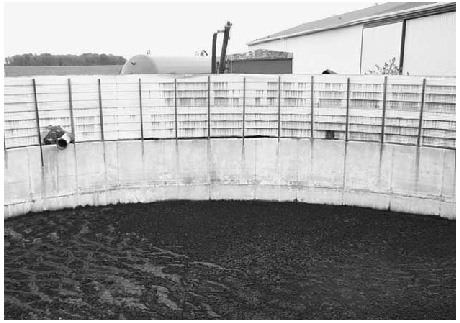

MANURE STORAGE

Some systems for storing the manure are more dangerous than

others. Below ground storage facilities, or pits, are more hazardous

than above ground structures. Systems that are covered by lids,

caps or slotted floors are more hazardous than uncovered systems.

Pump-out pits or caps can also be very hazardous. Leaks from

storage structures may also cause significant losses of fish

and other aquatic species if near streams or lakes.

The information and recommendations contained in this publication

are believed to be reliable and representative of contemporary

expert opinion on the subject material. The Farm Safety Association

Inc. does not guarantee absolute accuracy or sufficiency of

subject material, nor can it accept responsibility for health

and safety recommendations that may have been omitted due to

particular and exceptional conditions and circumstances.

Copyright

© 2002 Farm Safety Association Inc.

22-340 Woodlawn Road West, Guelph, Ontario (519) 823-5600.

Disclaimer and Reproduction Information: Information in NASD does not represent NIOSH policy. Information included in NASD appears by permission of the author and/or copyright holder. More