Tractor rollovers are the single deadliest type of injury

incident on farms in the United States. The latest figures

from the National Institute of Occupational Safety and Health

(NIOSH) suggest there are approximately 250 tractor rollover

fatalities per year. NIOSH estimates that there are approximately

4.7 million tractors in use on U.S. farms; one-half of them

are without rollover protection for the operator. This fact

sheet will closely examine tractor rollover protection issues.

Rollover Protection Structures (ROPS) are roll bars or roll

cages designed for wheel- and track-type agricultural tractors.

ROPS are designed to create a protective zone around the operator

when a rollover occurs. When used with a seat belt, the ROPS

will prevent the operator from being thrown from the protective

zone and crushed from an overturning tractor or from equipment

mounted or hooked to the tractor (see Figure 1).

Figure 1. A buckled seat belt keeps the operator within

the zone of protection of the ROPS during an overturn.

Three types of ROPS frames are available: a two-post frame

(with solid fold down versions), a four-post frame, and a

ROPS with enclosed cab. They all serve the same function:

protecting the operator in case of a tractor rollover.

- National data suggests that 1 of every 10 tractor operators

overturns a tractor in his or her lifetime.

- Tractors in the Northeast states have the highest rate

of overturn deaths and the lowest percentage of tractors

with ROPS.

- The one time effort in installing a ROPS will protect

whoever drives the tractor for the life of the tractor.

- The use of ROPS and a seat belt is estimated to be 99%

effective in preventing death or serious injury in the event

of a tractor rollover.

- The Occupational Safety and Health Act (OSHA) requires

an approved ROPS for all agricultural tractors over 20 horsepower

that were manufactured after October 25, 1976, and which

are operated by a hired employee.

- A ROPS normally limits the degree of rollover thereby

reducing damage to the tractor.

- A ROPS with enclosed cab also prevents tractor operators

from being knocked out of their tractor seat from rough

ground and low hanging tree limbs, provides protection from

the sun and other weather hazards, and reduces risk for

the unsafe practice of extra riders on tractors (see Figure

2).

Figure 2. A ROPS with enclosed cab gives the operator the most

protection from common hazards of tractor operation.

Between 1967 and 1985 U.S. farm tractor manufacturers provided

ROPS as optional equipment on most tractor models. This meant

that new tractor purchasers had to add the cost of a ROPS onto

the base price of a tractor. Because most farmers are cost conscious,

few added ROPS as an option. Even fewer pre-1967 tractors have

ROPS, yet many of these tractors are still in use. Beginning

in 1986, American tractor manufacturers began voluntarily adding

ROPS on all farm tractors sold in the United States over 20

horsepower.

The percentage of tractors in use and manufactured before the

voluntary ROPS agreement is high because farm tractors are often

in use for 30 to 40 or more years. Many newer tractors originally

sold with ROPS have been stripped of the protective roll bar

or roll cage because some farmers claim the ROPS structure blocks

their view during normal tractor operations. Another reason

often given for removing a factory-installed ROPS is that the

tractor won't fit into smaller spaces with a bulky roll bar.

Foldable ROPS are now available to reduce this problem (see

Figure 3).

Figure 3. A foldable two-post ROPS allows tractor operation

in low clearance situations without completely removing the

ROPS.

Figure 3. A foldable two-post ROPS allows tractor operation

in low clearance situations without completely removing the

ROPS.

ROPS are engineered to mount on specific tractor models and

designed to operate with the tractors mounting brackets and

frame. This provides a structure that is flexible, yet rigid

enough to withstand the loads produced during a tractor overturn.

Prototype ROPS must pass engineered, crush, static, and dynamic

tests to assure adequate performance before they are produced

for the public. These prototype ROPS must meet the standards

set by the Society of Automotive Engineers (SAE) (SAE J167,

J2194), and the American Society of Agricultural Engineers (ASAE)

(ASAE-S383.1).

The dynamic test involves hitting the tractor ROPS in a prescribed

manner with a 4,410 pound pendulum weight from behind and from

both sides. In order for a ROPS to pass the dynamic test, the

ROPS protective zone must remain intact and maintain the specified

distances from the operator. The ROPS can be made of any material

as long as the material meets temperature requirements and passes

the tests set forth by the standards. Typical ROPS provided

by manufacturers are made of steel that will not fracture in

cold temperatures and are precision welded. The goal of the

ROPS is to absorb the impact energy without excessive deformation

to create a zone of protection for the operator.

Some ROPS frames and enclosed cabs are equipped with overhead

canopies to protect the operator from falling objects. Canopies

that protect against falling objects ñ called FOPS (falling

object protective structures) ñ must be properly designed and

certified. Such canopies are recommended when using front-end

loaders, working in the woods, or in other circumstances where

falling objects may be a hazard. FOPS must be designed according

to SAE and ASAE standards. To be sure that a canopy is a FOPS,

check with the ROPS supplier or the equipment dealer.

Farm tractors (including some lawn and garden models) should

have a factory installed ROPS with a seat belt. These ROPS are

certified to meet maximum rollover impact and dynamic forces.

Modification of the factory installed ROPS (cutting, grinding,

drilling or welding) is unauthorized and unwise. Modification

of the ROPS design can impair the ROPS ability to carry out

its function (i.e. providing a protective zone to save a human

life) in the event of a tractor overturn. Factory installed

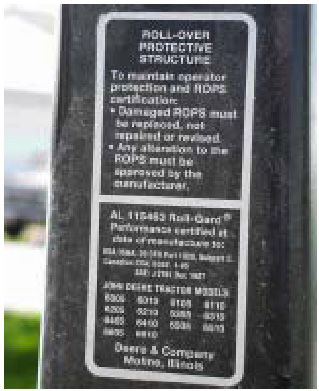

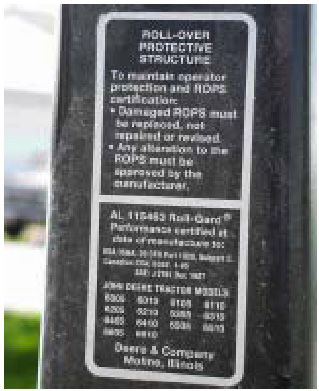

ROPS will have a certification label attached to the roll bar

stating that the roll bar meets SAE/ASAE/ OSHA standards. See

Figure 4 for a typical example. It is important to check for

this label on imported tractors.

Figure 4. This certification tag indicates the ROPS meet

nationally approved standards for operator protection during

a rollover.

Figure 4. This certification tag indicates the ROPS meet

nationally approved standards for operator protection during

a rollover.

It is necessary to inspect and service a ROPS and seat belt

periodically to check for extreme rust, cracks, or other sign

of wear. Any of these could cause a failure of the ROPS during

a rollover. If there are signs of wear, the manufacturer or

dealer should be consulted to determine the suitable course

of action.

ROPS can also be abused or misused. Holes should never be drilled

into the ROPS frame, nor should a piece of steel be welded onto

the frame. If lighting or other light attachments are needed,

they should be clamped onto the ROPS. A ROPS should not be used

as a point of attachment for a chain, hook or cable. Pulling

with the ROPS could damage it and result in a rear overturn.

If a tractor with ROPS does overturn, the ROPS should be replaced

because it is specifically designed to bend to absorb the energy

generated by the tractor contacting the ground. ROPS are only

designed and certified to withstand a single overturn.

Many farm tractors manufactured since 1967 can be retrofitted

with a ROPS. Tractor companies and aftermarket manufacturers

have designed and developed ROPS for most tractor models. Manufacturers

such as AGCO, Case-IH, Kubota, New Holland and Deere and Company

offer low cost retrofit ROPS kits for tractors manufactured

from the mid 1960ís to 1985. ROPS for many older and smaller

tractors can be purchased for $600 or less. Agricultural equipment

dealers are approved to install a retrofit ROPS and seat belt.

Installation charges are normally in addition to the cost of

the ROPS.

A listing of ROPS retrofits for farm tractors manufactured since

1967 has been compiled by the National Farm Medicine Center,

Marshfield, Wisconsin, in a publication called, A Guide to

Agricultural Tractor Rollover Protection. This guidebook is

available on the web at

http://www.marshfieldclinic.org/nfmc/pages/default.aspx?page=nfmc_rops_guide/. Local equipment dealers should also have

information on ROPS retrofitting for their brands of tractor.

ROPS for some older models of tractors may not be available

even though one is listed by a ROPS manufacturer. This is because

a ROPS manufacturer often will not produce a specific ROPS for

an older tractor until an order has been placed. An order for

just one ROPS may mean the cost will be prohibitive to the tractor

owner.

Because of the severe impact and dynamic forces present during

a rollover, it is important that a ROPS be properly designed,

manufactured, and installed. If the ROPS is too rigid or too

flexible, injury could occur to the operator during a rollover.

Homemade ROPS are not recommended because they may not be properly

designed, built, or installed. Poor welds and undersized bolts

could fail under the impact and stress of a tractor overturn.

Farmers, local hardware stores and welding shops do not have

the special steels, bolts or welding supplies required for an

approved ROPS. Nor do they have the testing equipment that is

needed to certify that a ROPS meets design standards. A homemade

ROPS also exposes the owner and builder of the ROPS to liability

damages should a tractor overturn and the homemade ROPS fail.

A seat belt is an integral part of the tractor rollover protective

system as it keeps the operator within the protective zone created

by the roll bar or roll cage. The seat belt assembly must also

conform to engineering standards.

A ROPS alone will not provide full protection to the operator

when there is a tractor overturn. A seat belt must be used in

combination with the ROPS to provide the highest degree of safety.

Without a seat belt, the operator will not be confined to the

protective zone, and may be crushed by the tractor or even the

ROPS itself.

Many farmers give the excuse that because they won't wear the

seat belt, they won't bother to install a ROPS. While a ROPS

alone won't completely protect the operator, it will provide

considerable protection. Precise statistics are not available

but what is known is that:

-

Few tractor operators buckle their seat belts while operating

a tractor;

-

There are an estimated 2,000 ROPS equipped tractor overturns

each year;

-

There is no data at the national, state, or local level to suggest

these ROPS equipped tractor overturns are fatal to the tractor

operators.

While roll bars and seat belts together are the most effective

system for operator protection from a tractor that is overturned,

the ROPS portion of the system provides the bulk of the protection.

Installation of a ROPS on all tractors is an important step

toward agricultural injury prevention.

Publication #: E42

The Pennsylvania State University is committed to the policy

that all persons shall have equal access to programs, facilities,

admission, and employment without regard to personal characteristics

not related to ability, performance, or qualifications as determined

by University policy or by state or federal authorities. It

is the policy of the University to maintain an academic and

work environment free of discrimination, including harassment.

The Pennsylvania State University prohibits discrimination and

harassment against any person because of age, ancestry color,

disability or handicap, national origin, race, religious creed,

sex, sexual orientation, or veteran status. Discrimination or

harassment against faculty, staff, or students will not be tolerated

at The Pennsylvania State University. Direct all inquiries regarding

the nondiscrimination policy to the Affirmative Action Director,

The Pennsylvania State University, 201 Willard Building, University

Park, PA 16802-2801, Tel 814-865- 4700/V, 814-863-1150/TTY.

Disclaimer and Reproduction Information: Information in

NASD does not represent NIOSH policy. Information included in

NASD appears by permission of the author and/or copyright holder.

More