In the Headlines!

Tractor Power Takeoff Amputates Arm

A 30-year-old farm laborer was driving a farm tractor which

was pulling a dairy feed wagon. The power-takeoff unit at

the rear of the tractor was driving the feed-dispensing auger

system inside the feed wagon. (A power-takeoff unit (PTO)

is an extension of the tractor transmission shaft used to

power implements with the tractor engine.)

This is a common method of feeding dairy cows; the auger both

mixes the feed and pushes it out. The PTO was apparently not

functioning correctly, and the employee left the tractor engine

idling and climbed off the tractor to check the attachment.

The employee was standing next to the PTO when he turned to

reach up to pull the hydraulic lever on the rear of the tractor

which engages or disengages the PTO. As he did this, his left

shirt sleeve was caught on the rotating PTO shaft.

The employee was wound around the PTO shaft as it rotated. The rotation of the shaft wedged him into the metal frame around the PTO shaft and nearly sheared off his arm. Also, his head struck the metal frame. He received a 2-inch laceration on his scalp near the back of his head as well as a cervical fracture. The laborer's body jammed the PTO and caused the idling tractor engine to stall. He lost consciousness for an unknown length of time.

When

he regained consciousness, he called for help and was found

by coworkers who contacted the local ambulance service. The

PTO shaft was disconnected in order to extricate the injured

worker's arm. His left arm was almost detached about halfway

between shoulder and elbow, connected only by skin and muscle.

This worker had been employed at the dairy for 3 months, although

he had worked at different dairies for approximately 10 years.

Since beginning work at this dairy, he had received no safety

training related to equipment, job tasks, or hazard identification.

Tractor

Overturn Crushes Operator

A tractor operator was left in a field to mix fertilizer using

an industrial tractor equipped with a front-loader and a back-hoe.

Other employees driving along the road spotted the tractor

lying on its side in a drainage ditch. They found the operator

pinned under the tractor ROPS (rollover protective structure);

his chest was crushed.

The workers drove to the farm office and informed the foreman.

The foreman told the secretary to call 911 and went to investigate.

The fire department, the sheriff's department, the Highway

Patrol and the coroner's office responded to the call, but

the operator was obviously deceased, and was pronounced dead

at the scene.

The incident occurred approximately 50 yards from the initial

work area. The operator had been mixing fertilizer with the

front-loader, and then drove the tractor down a private dirt

road on the farm. The tractor was in first or second gear,

and the estimated top speed was five miles per hour. For an

unknown reason, the tractor traveled off the side of the road,

slid into a drainage ditch about three feet deep, and tipped

nearly perpendicular to the roadway. The driver was not wearing

his seat belt. He fell off the seat as the tractor overturned

and was then crushed under the ROPS.

When the tractor was found the ignition was still on. The

metal insert portion of the seat belt was missing, preventing

the belt from being fastened. The back-hoe locking pin was

not in place, although the back-hoe was positioned against

the rear of the tractor. The front loader bucket was pushed

into the dirt. No signs were found of skidding or loss of

control.

I.

Overview

Deaths involving tractors contribute to agriculture having

one of the highest on-the-job annual death rates — 20.3

deaths for 100,000 workers nationally. That statistic from

1997 has been virtually unchanged for many years. In a 1999

study conducted by the Deep-South Center for Agricultural

Health and Safety, it was found that, on average, 21 adults

had died each year in Florida agriculture in recent years.

At

least 74 of those deaths involved machinery, including tractors

overturning and crushing their drivers. Across the nation,

approximately 36 percent of the agricultural work fatalities

in 1997 involved a tractor, and 19 percent involved other

machinery, according to the National Safety Council.

Safer tractor operations and the use of protective equipment

could prevent many of the deaths and injuries involving tractors.

Owners, managers, and tractor operators all play a major role

in making tractor operations safer. Owners have responsibilities

for providing a safer environment and safer equipment. Managers

coordinate maintenance designed to ensure the safety of equipment,

as well as safety policies and programs. The final responsibility

for making the operation of tractors safer lies with the tractor

operators themselves.

It's often only when an incident occurs that people become

focused on what might have prevented injury or loss of life.

The following pages give guidance to agricultural employers

about how everyone in their operation can work together to

make using tractors safer.

This publication is one in a series of UF/IFAS Extension circulars

devoted to tractor safety for various audiences. The complete

series is (see also the Resources section at the end of this

publication):

II. Foundations

of Tractor Safety: Safer Operators on Safer Tractors in Safer

Environments

The three major elements which must be considered when developing

programs to make tractor operations safer are:

We have

control over some aspects of these elements; for example,

setting up fields so that there is adequate turning room at

the ends of rows is a safety factor entirely within human

control. So is the speed at which the tractor is operated,

as well as if a rollover protective structure (ROPS) and seat

belt are used. However, there are elements over which we have

no control. In those cases, operations must be modified in

order to complete the job safely.

Deaths and injuries result from hazards. A particular driver

may be safety-conscious and driving a tractor equipped with

safety features, yet he/she might drive into a hazardous environment

with a false sense of security; or because an environment

is considered "safe", an owner or driver might tolerate

an unsafe tractor. Either of these situations is likely to

result in an incident. Preventing incidents means recognizing

hazards and avoiding them or, at least, taking appropriate

precautions if they must be encountered.

An operator who uses good safety practices on a tractor with

safety features reduces the chances of being killed or injured.

A.

A Safer Operator

Management's responsibility does not end with a safer environment

or a safer tractor. There are still responsibilities in selecting,

training, motivating, and supervising tractor operators.

Consider the following in selecting tractor operators:

A

14- or 15-year-old may operate a tractor as a student

in a bona fide agricultural education program or if

he/she has received a certificate of completion from

a 4-H Federal Extension Service Training Program or

a U.S. Office of Education Vocational Agriculture Training

Program.

Youths of any age can be employed by their parents to

work on a farm they own or operate. However, remember

the exemption does not eliminate the hazard.

Management

has a responsibility for training tractor operators. All employees

who operate agricultural tractors shall be informed of safer

operating practices when first assigned to operate a tractor

and at least annually thereafter. Brief ongoing "tailgate

sessions" are recommended on a weekly or monthly basis.

The following rules apply to all tractor operators employed

in agribusinesses under the jurisdiction of the Occupational

Safety and Health Act (the Occupational Health and Safety

Act of 1970, or OSHA). Although these rules do not govern

everyone, they should be applied to all tractor drivers.

1.

More Tractor Operator Tips

Tractor

operators should appreciate that tractor driving is a privilege

extended only to trustworthy and dependable employees. Drivers

should recognize that they play an important role in a total

safety program — a program that makes every reasonable

effort to provide a safer environment and a safer tractor

for a competent, safer driver.

Tractor drivers should report all unsafe conditions to their

immediate supervisor. The goal is to prevent property damage

and injuries. Close calls should also be reported.

Supervisors have the responsibility of seeing that all tractor

operators have a complete understanding of all instructions

and rules. They also need to verify that the instructions

are followed and that appropriate corrective action is taken

when intentional or unintentional violations occur.

Tractor operators must have a clear understanding of all instructions

and rules. They need to recognize that repeated violations

of safety practices may result in their reassignment to a

position that does not involve driving a tractor.

Managers might consider giving incentives to tractor operators

who achieve a credible safety

record. Possible incentives for a tractor operator who has

gone through a season without a personal injury or property

damage incident include a small salary increase and/or additional

paid vacation days.

Employers have also found that small rewards -- such as a

meal, a local merchant gift certificate, or cash bonus --

presented monthly, are effective in promoting safety.

2.

Operator's Responsibilities

(See Section V. Tractor Operator Checklist.)

Managers

should consider explaining the following responsibilities

to tractor operators.

Operators are responsible for daily pre-operational checks

of their tractors — even if a shop mechanic has responsibility

for servicing it. This pre-operational check needs to include

at least the following activities:

A tractor

might require additional pre-operation checks. The operator

should know what they are and should perform them daily or

more frequently. He/She can determine which checks are needed

by reviewing the maintenance manual for the tractor. A tractor

is not the only "machine" that needs a pre-operation

check. The operator does too.

3.

Important Checks

Operators should conduct a pre-operational check of their

clothing.

The incident you prevent might well save your life and the lives of others.

4.

Shortcuts are Short-sighted! or, Invest Seconds, Save Lives!

Stepping over a power takeoff instead of walking around a

tractor might seem like a time-saving shortcut, but it exposes

you to a much greater risk of injury or death.

Often, there's a "recommended safe way" of doing

a task and then there's another way that seems quicker but

is more hazardous. Many people use the more dangerous shortcut

to save time.

However, timed studies show that the time invested in doing

a task safely is quite insignificant, especially when compared

to the costs of injuries or possible death that could result

from the extra hazards involved in the shortcut.

Here are some examples of the small amount of time it takes to be safe. To put these times in perspective, the total time invested for 100 repetitions of a task was calculated. Note that 100 repetitions may occur over an entire year/season. For example, stepping over the PTO may take 2 seconds less time than walking around it. So, if this was done 100 times in a season, you would save only 3.33 minutes. However, every one of those 100 times, you put yourself at risk for injury or death. (See Tables 1 and 2.)

B.

A Safer Tractor

Modern tractors are much safer than tractors of 20 or 30 years

ago. Rollover protective structures (ROPS) and seat belts

now prevent many deaths and injuries from tractor overturns.

Improved hitch designs and weight distribution have made tractors

more stable. Improved shielding of power takeoff shafts, improved

hydraulic designs, improved brakes, wider wheel bases, better

visibility, and other features such as running lights and

adjustable seats have also contributed to safer tractors.

Despite modern safety improvements, there are still dangers

that come with driving a tractor. These dangers can be reduced

if the tractor operator understands the tractor and maintains

and operates it properly.

A few

modern features, however, have actually increased the potential

danger.

Management has the responsibility of providing operators with safer tractors. Consider the following ways to improve tractor safety.

1.

Rollover Protective Structures (ROPS)

Nearly one half of tractor-related deaths are due to tractor

overturns.

The side overturn is the most frequent type of overturn. Studies

indicate 75-85 percent of overturns are to the side. A tractor

has a high center of gravity, thus, sharp turns and/or high

loads can cause it to overturn quite easily — and at

relatively low speed. Centrifugal force can cause a tractor

to overturn if the direction of travel is changed. For example,

when a tractor's right front wheel veers into the road ditch,

the natural reaction of the operator is to steer it back onto

the roadway, however, the forces will pull the tractor over

on its side.

The second

type of overturn is to the rear. These overturns may be less

frequent, but without a ROPS, they are the most deadly. It

is estimated that, without a ROPS, 85 percent of rear overturns

result in the operator's death.

Rear overturns occur when the tractor can't move forward and

the rear axle torque causes the tractor to pivot around the

rear axle. The entire event can happen in as little as 1.5

seconds; the tractor can reach the point of no return in as

little as 0.75 seconds. There is no time for the operator

to react. Rear overturns are often due to pulling a load uphill,

being stuck in the mud, or attempting to pull a load that

has been hitched above the drawbar.

When possible, operate a tractor equipped with a rollover

protective structure (ROPS). Most tractors should be equipped

with a ROPS and seat belt. However, certain tractors are exempt,

including:

However,

exemptions are not to be used as an excuse for not using safety

features. If the use of the tractor permits ROPS and seat

belts, they need to be provided. An exemption doesn't eliminate

hazards.

Always wear a seat belt on a tractor with a ROPS. If an overturn

occurs, the seat belt helps keep the driver within the safety

zone that the ROPS creates. Seat belts are not to be used

on tractors without a ROPS since, in that case, an operator

constrained in the seat would be crushed. Without a seat belt,

the driver may be thrown around in the cab, which can result

in severe injuries or unconsciousness. Either of these could

make it impossible for the driver to escape the cab, which

could be fatal, especially if the tractor has overturned into

a canal.

2.

Frequently Asked Questions about Rollover Protective Structures

(ROPS)

How common are tractor overturn injuries?

Tractor overturns are the leading cause of work-related deaths

in agriculture.

Can overturn injuries be prevented?

The use of a ROPS and seat belt is 99 percent effective in

preventing deaths and injuries from overturn.

Why is a seat belt needed with the ROPS?

The seat belt keeps the operator within the zone of protection

in an overturn. A seat belt must not be used on tractors without

a ROPS because it will prevent the operator from jumping clear

in a dangerous incident.

How do I know if a ROPS is available for my tractor(s)?

The ROPS directory, prepared by the National Farm Medicine

Center in Marshfield, Wisc., contains this information The

directory is distributed to county extension offices and equipment

dealers. Most manufacturers offer ROPS at affordable prices.

Contact your dealer for details. The ROPS directory is available

on the Internet at http://www.marshfieldclinic.org/nfmc/?page=nfmc_rops_guide.

Or you can check with your local tractor dealer.

I

can't afford ROPS for all my tractors, but I want to reduce

my risk of being hurt in an overturn. What can I do?

Safety can be improved by using a tractor equipped with a

ROPS for riskier operations. The value of a ROPS is such that

trading in an older tractor for a model equipped with a ROPS

might be worth considering.

If ROPS are so great, why can't I make my own?

Only ROPS that have been tested to meet specific standards

are acceptable. Tractors with ROPS that haven't been approved

can split during an overturn. Anything less than an approved

ROPS provides a false sense of security. Altering a ROPS by

welding something onto it or by drilling holes in it can make

it less effective. The dynamic forces that act upon a ROPS

during a tractor overturn make it crucial that a ROPS be properly

designed, manufactured, and installed. The ROPS and tractor

must work together as a system in order to stay together as

a unit in the event of an overturn.

Won't a ROPS limit the way I can use my tractor?

Few owners actually remove a ROPS because of interference.

ROPS that fold down are available for many tractors.

Some of my tractors have cabs. Isn't the ROPS a part of

the cab frame?

Many older tractors may have what is known as a weather cab,

meaning a ROPS is not part of the frame. In an overturn, these

cabs can be more deadly since they provide no chance for quick

escape, thus increasing the chances of being crushed.

How do I know if the cab on my tractor has a ROPS as part

of its structure?

Look for a label indicating it has an OSHA-approved ROPS;

most tractors manufactured after 1976 should have these labels.

However, labels are not located in a uniform spot, and the

cab may cover them up. Look for a seat belt. Manufacturers

only install seat belts on ROPS-equipped tractors. Consult

the dealer.

3.

More Tractor Safety Tips

4.

Bypass Starting Dangers

Shortcuts are common in agriculture, but they are dangerous.

Bypass starting is a very dangerous shortcut.

The term "bypass starting" points to its danger.

It bypasses all the safety-start and neutral-start switches

in the tractor's electrical and hydraulic systems. The problem

comes when someone tries to bypass-start a tractor or other

piece of equipment that is in gear. The person can then get

pulled down by the drive wheel and be crushed. The runaway

tractor can also injure or kill others in the area.

Often operators or mechanics bypass-start an engine because

of a maintenance problem with the tractor's neutral-start

switch. It's a good idea to immediately repair mechanical

problems that might make bypass starting tempting. Remember,

every death or injury due to bypass starting could have been

avoided.

5.

Safety Switch Check

Periodically check switches to make sure they are in working

condition. This helps avoid the temptation of trying to bypass-start

an engine. Following the steps below only takes a few seconds.

6.

Having One Driver per Tractor is Ideal

Scheduling one operator to one tractor has several advantages.

Operators assigned to drive different tractors tend to become

confused in crisis situations. The controls may be different,

and a split-second delay in reacting to a crisis can result

in an overturn or other incident.

When more than one operator drives the same tractor, the tractor

is no longer considered "mine" by any one employee.

Care of the tractor diminishes, and the blame for lack of

maintenance and/or damage is shifted to the "other person."

It is also easier for an operator to not check things because

he/she thinks the other drivers have taken care of them.

C.

A Safer Environment

Tractor overturns in canals, ditches and washouts are common.

The steep slopes and loose soils in these environments are

serious hazards. Other hazards are found on public roads,

blind corners, narrow bridges, culverts, sharp turns, steep

terrain and slippery surfaces.

Inspect the environment in which tractors will be used. Identify

the hazards and take action to eliminate them. Implement the

following suggestions to reduce the environmental hazards:

III. Safer Tractor

Operations

A. Dangers of Extra Riders

It was going to be a record harvest. The owner of the operation

could see light at the end of the tunnel – paying off

loans, updating equipment, maybe a little left over for a

family vacation. The farm manager sent the workers out to

the field. It was a beautiful morning, and the workers were

laughing and joking. They hopped up onto the tractors to catch

a lift to the field. As the merriment continued, one of the

tractors drove into a rough part of the field. Before anyone

knew what had happened, one of the workers had lost his grip

on the tractor he was riding, and the tractor ran over him.

He drowned in about fifteen minutes as his punctured lung

filled with blood. There was no harvest that day, just anxious

workers and a bereaved family. The following days were taken

up with the funeral, the OSHA investigation, the insurance

company, and a pending lawsuit by the victim's family.

This story is a compilation of details from many incidents

of this type that have occurred in Florida and elsewhere in

recent years. In most incidents involving extra riders, victims

fall off or are thrown from the tractor during a rough ride

or when a tractor overturns. In these situations, extra riders

can be run over by either the tractor or by an implement being

towed, or both. In an overturn, the tractor often crushes

the extra rider.

These incidents are double tragedies because they can be prevented

so easily. The following information discusses the serious

risks that extra riders face.

1.

Why Take the Risk?

Tractors are not passenger vehicles. Except for those built

with instructional seats, they are designed for one person

to operate.

Passengers on tractors can interfere with safe operation of

a tractor. The extra rider can distract the operator, block

access to controls or obstruct the operator's vision.

Tractors

(except those with instructional seats) are designed to provide

protection for only one person, the operator. All tractors

manufactured since 1976 have a special rollover protective

structure -- a ROPS -- that provides a safe environment for

the operator if the tractor overturns. The use of the seat

belts on tractors with ROPS will protect the operator from

serious injuries.

Extra riders have no such protection. There is no safe environment

for extra riders on tractors. Older model tractors without

ROPS offer no overturn protection for operators or extra riders.

Many people have the mistaken idea that enclosed cabs protect

extra riders. This notion only gives tractor operators a false

sense of security. Many tractor runover deaths happen when

a person, often a child, falls out of an enclosed cab. An

enclosed cab can reduce the chance that a rider will be bumped

off a tractor, but it can't eliminate the risk. The small

measure of protection from an enclosed cab is not a guarantee

of safety for extra riders. Door latches may not be fully

latched; latches can be bumped; and children can become restless

and tamper with latches and controls. Note: Tractor models

with instructional seats are limited to cab tractors.

2.

Causes of Runovers

There are many reasons why extra riders are thrown from the

tractor, frequently resulting in death. These include:

Operators

may think they can respond quickly and stop the tractor if

something occurs, especially if the tractor is moving very

slowly or if only simple tasks are being performed. The most

common comment from people involved in tractor runovers is

how quickly the incident occurred (see Table 3).

Runovers can also occur when the tractor is involved in an

incident. One common scene occurs when a rider is thrown after

the tractor hits a building, bridge, or another vehicle. If

the tractor overturns, the operator and the rider are both

in danger.

3.

The "No Riders" Rule

The only way to prevent extra rider injuries or deaths is

to prohibit riders on tractors except for those actually involved

in training on a tractor equipped with an instructional seat.

Consider making a permanent policy for not allowing riders

on tractors.

Make sure all tractor operators observe the "NO RIDERS"

rule. Discuss the importance of this rule with managers and

employees. It's also helpful to post "NO RIDERS"

decals on all tractors to remind others about the policy.

"NO RIDERS" decals may be purchased from the Farm

Safety 4 Just Kids organization (1-800-423-5437). Many implement

dealerships also carry these decals.

"No

Riders" Decal.

The most effective way to observe the NO RIDERS" rule

is to eliminate the need for extra riders on tractors. Use

other vehicles, such as trucks or motor vehicles, when transporting

workers to fields or distant work sites. Here are some tips:

4.

Problems on Other Equipment

Other farm equipment may be unsafe for extra riders, too.

Most all-terrain vehicles, skid steer loaders, and riding

lawnmowers are designed for one person.

Some combines and other equipment have extra seats. Seats

for extra riders should be added only by the manufacturer

because many factors are considered in designing them for

safety. A makeshift seat added to farm equipment cannot ensure

safety. Enforcing a "NO RIDERS" rule may be the

single most important action in protecting people on farms

or ranches. The rule may challenge years of tradition, but

it provides a safer way to pass on the agricultural heritage.

B.

Road Safety for Tractors and Farm Machinery

Each year, incidents involving tractors and other farm machinery

occur on public roads, causing deaths, injuries, and costly

equipment damage.

Collisions with other vehicles make up nearly half of these

incidents. Running off the road, overturning, striking a fixed

object or the operator falling off the equipment make up the

remainder.

About one-third of tractor-related deaths occur on public

roads, according to the National Safety Council. Many people

assume that these collisions happen during bad weather or

hazardous conditions. Studies have repeatedly shown that nearly

80 percent of tractor-motor vehicle collisions occur on dry,

straight roads in daylight.

Here are some practical tips that can help. Although most

of these points may seem obvious, they are nonetheless important

to review.

1.

Common Causes of Collisions

Nearly half of all collisions between motorists and farm implements

involve one of two scenarios —The left-turn collision

or the rear-end collision. The number of incidents involving

each scenario is about equal.

a. Left-Turn Collision

The scenario: The left-turn collision occurs when the tractor

is about to make a left turn at the same time that a motorist

tries to pass.

Why it happens: Like tractor/semi-trailer drivers, tractors

sometimes need to make wide left turns. They may swing to

the right before making a left turn because they need extra

room to line up with a farm gate or driveway. This maneuver

can confuse motorists, especially if they think that the tractor

operator is moving over to let them pass. Tractor operators,

especially when towing equipment, have limited visibility

and may not see the motor vehicle.

How to avoid: Tractor operators can reduce the potential for

the left-turn collision by installing extension mirrors on

the tractor to improve visibility. A sticker that is often

seen on semi-tractor-trailers is a good reminder to motorists:

"If you can't see my mirrors, I can't see you."

This sticker can be placed on farm equipment to provide motorists

with more information.

b. Rear-End Collision

The scenario: The rear-end collision happens because a motorist

doesn't see the farm machinery in time.

Why it happens: It's easy to misjudge speed when approaching

a slow-moving vehicle. In most cases, there are only a few

seconds to react and slow down. For example, if the motorist

is driving 55 miles per hour and comes upon a tractor that's

moving 15 miles per hour, it only takes five seconds to close

a gap the length of a football field.

Another way of looking at it: If the driver of a motor vehicle

that is traveling at 50 miles per hour spots a tractor 400

feet ahead on the road and the tractor is moving at 20 miles

per hour, the motorist has less than 10 seconds to avoid a

rear-end collision.

In those

ten seconds, the motorist must recognize that a dangerous

situation exists, determine the speed at which the tractor

is moving, decide what action to take and apply the brakes

hard enough and long enough to avoid a collision.

How to avoid: Use marking and lighting (as described in the

"Lighting and Marking" section of this publication)

to provide motorists with the information they need to recognize

the hazard.

c.

Sideswipe Collision

The scenario: When a motor vehicle meets or attempts to pass

a farm vehicle, it is sideswiped by the tractor/equipment.

Why it happens: Some farm operators haul equipment that is

extra wide or especially long, but some motorists do not take

into account the width or length of the equipment or the sway

of the tractor and implement. Also, equipment takes up more

available roadway when approaching bridges, mailboxes, or

other shoulder obstructions.

How to avoid: In order for oncoming and passing traffic to

better assess the width of farm equipment, reflective tape

and materials should be used to mark the extreme front and

rear points of the machine.

d.

Head-On Collision with Other Motor Vehicle

The scenario: While a motor vehicle is passing a farm vehicle,

it is confronted by another motor vehicle approaching head

on. There is no time to get off the road and a head-on collision

occurs.

Why it happens: As in the Sideswipe, a driver may fail to

appreciate the length of the farm equipment to be passed and

be forced to spend a longer time in the passing lane. Add

to this that the driver's view when preparing to pass may

be blocked by the farm equipment.

e.

Head-On Collision with Vehicles

The scenario: An on-coming motorist collides head-on with

the towed implement that is wider than the tractor.

Why it happens: Wide equipment poses a special hazard, especially

at night, because oncoming traffic does not realize that the

tractor is pulling equipment that extends across the centerline

and into the opposite lane of traffic until it is too late

to react.

How to avoid: If at all possible, keep road travel of wide

equipment to a minimum, especially at night. Equipment that

is well-marked and well-lit will provide motorists with better

information to help them react in time. Reflective materials

should be used to mark the extreme front points of the machine.

2.

Escort Vehicles

At times, tractors or the equipment they are pulling cross

into the oncoming traffic lane, especially on narrow rural

roads. In these situations, consider using an escort vehicle

equipped with flashing yellow lights. Remember that equipment

can obscure rear tractor lights.

Even if an escort vehicle is not required by law, it is good

practice. For large equipment, the local police, sheriff or

highway patrol may provide this service.

Escort vehicles are required by state laws under certain conditions.

These conditions are listed in Table 4. This table is not

definitive. If you have any question about an oversize vehicle,

contact your Department of Transportation permits division.

For Florida, additional requirements for the kind of vehicle

that may be used as an escort, as well as for its marking

and lighting are specified in the Florida Administrative Code

(F.A.C.) Section 14-26.0012. Contact your state Department

of Transportation for complete details about the kind of vehicle

which is acceptable for escort use, as well as the proper

marking and lighting of escort vehicles.

3.

Lighting and Marking -- Summary of ASAE Standard S279.10

Remember the reason for marking and lighting is to provide

motorists with better information. Marking and lights that

are obscured or not at the motorist's eye level do not provide

"quick reflex" information for the motorist.

An excellent

example of this principle was the placement of a brake light

in the rear window of cars. A study of its effectiveness was

conducted among a test group of New York City cab drivers.

Placement of the light at the motorist's eye level helped

motorists to see brake lights several cars ahead and reduced

the number of rear-end collisions by 50%. For the collisions

that did occur, damages were reduced by one-third. This happened,

not by reforming or changing drivers, but simply by providing

them with better information.

What are ASAE Standards? ASAE (American Society for Agricultural

Engineers) is the professional society for those interested

in engineering knowledge and technology for food and agriculture,

and related industries and resources. Standards are based

on experience and research, and they are developed by committees

that include qualified people from producer, consumer, and

general interest groups.

This lighting and marking standard applies to all tractors,

other self-propelled farm machinery, and towed machinery used

for farm operations (for more details see standard ASAE S390.1)

which might be driven or towed on any road that is also accessible

to the public. Self-propelled machines and towed machines

are considered separately in the standard. The following is

only a summary of ASAE Standard 279.10 OCT98 "Lighting

and Marking of Agricultural Equipment on Highways." Consult

the standard for exact details about the specific types of

lights and their placement.

a.

General Recommendations for Lighting Self-Propelled Equipment

The standard recommends six features related to lighting self-propelled

equipment, which includes tractors. The standard defined the

proper lateral and vertical placement of lights; in general,

lights should be no lower that 3 ft from the ground or more

than 10 feet high.

Headlamps. — Two standard headlamps should be mounted

at the same height and spaced as far apart as possible, the

same distance on either side of the centerline. The standard

also defines how bright headlamps should be.

Work

lamps. — The equipment should be fitted with work

lamps. Rear-facing work lamps should not be used on the highway,

but others should be used to illuminate the area near the

equipment on its sides and front.

Taillights. — Two red taillights should be mounted

at the same height, as far apart as possible, and the same

distance on either side of the centerline. Taillights should

be at least 3 feet from the ground and not more that ten feet.

Warning Lights. — Extra-wide vehicles (12 ft or more)

should have flashing amber lights marking the sides of the

vehicle to reduce the danger of sideswipes. The lamps should

flash in unison at 60 to 85 times per minute.

Turn Indicators. — In addition to the red taillights,

the equipment should carry turn indicators. When a turn indicator

is on, the warning light on the side of the flashing turn

signal should flash faster, up to 110 flashes per minute,

while the warning light on the side opposite the turn should

burn steady and not flash.

Seven-terminal Receptacle. — Details of the seven-terminal

receptacle, for machines commonly used with equipment, are

defined in the standard. Towed equipment needs to have the

matching seven-pin plug. The wiring of the plug and receptacle

are described in the standard.

b.

General Recommendations for Marking Non-self-propelled Equipment

Marking refers to using reflectors, reflective materials,

and specific signs to make the presence and the size of towed

equipment obvious to other motorists. The general requirements

for marking self-propelled equipment are:

Rear Reflectors —- Red reflectors visible to the

rear up to a distance of 600 ft should be used to mark the

outermost side extensions of the equipment.

Front Reflectors -— Yellow reflectors visible to

the front should mark the extreme left and right of equipment,

especially if it is wider than the towing machine.

Conspicuity

Material -— Two kinds of material visible to the

rear should be used: retroreflective material that means the

material or device reflects back to the light source, and

red-orange non-reflective, fluorescent material. Conspicuity

material visible to the front should be yellow.

Slow-moving Vehicle (SMV) Emblem —- This triangular

emblem should be visible to the rear of any slow-moving machinery

(<25 mph). Remember: point up!

If Tractor Illumination Is Obscured - Towed equipment

should carry any lighting that it obscures on the tractor.

For example, if the towed equipment blocks a tractor's taillights

from the view of following motorists, the towed equipment

should carry taillights. The same is true for the tractor's

flashing red warning lights and its turn indicators.

If the Tractor's SMV Emblem Is Obscured - The SMV emblem

must be visible to following motorists. If the equipment being

towed obscures the SMV emblem on the tractor, then one must

be mounted on the towed equipment.

c.

Special Recommendations for Lighting and Marking Non-self-propelled

Equipment

The non-self-propelled equipment that is towed by tractors

should have its own lighting and marking. In many cases, the

standard has special recommendations based on the width or

length of the towed equipment.

Towed equipment should be marked and lighted so that it is

clearly visible from the rear and the side. It is important

that the full width and length of the equipment be obvious

to motorists who are approaching quickly from the rear, who

are trying to pass slow-moving-equipment, or who are approaching

as oncoming traffic.

Equipment

Width and Length

The following special requirements apply in these situations:

Extra Width: The towed equipment extends:

Front-Mounted Equipment: The attached equipment is in front of the tractor (see 4 below)

more

than 4 ft behind the hitch point on the tractor (see 5

below), more than 16 ft behind the hitch point on the

tractor (see 6 below),

more than 25 ft behind the hitch point on the tractor

(see 7 below).

1) The

towed equipment extends more than 4 ft to the left of the

tractor's centerline.

Special lighting requirements — Covered above under "If

Tractor Illumination Is Obscured."

Special marking requirements — At least one amber or

yellow reflector visible to the front positioned to indicate

as nearly as practicable the left projection of the equipment.

2) The

towed equipment extends more than 4 ft from the tractor's

centerline in either direction.

Special lighting requirements — Covered above under "If

Tractor Illumination Is Obscured."

Special marking requirements — In addition to the amber

or yellow reflector required for equipment that extends more

than four feet to the left of the machine centerline, at least

two red reflectors visible to the rear and mounted to indicate

as nearly as possible the extreme left and right projections

of the equipment.

3) The towed equipment is more than 12 ft wide (or extends more than 6 ft from the centerline in either direction).

Special

lighting requirements — Extra-wide towed equipment should

have flashing amber warning lights visible front and rear,

red tail lamps, and turn indicators. The warning lights should

flash in unison with the warning lights on the tractor.

Special marking requirements — 1) Visible to the rear:

Red retroreflective material and non-reflective red-orange

fluorescent material. The retroreflective material should

mark the left and right extremes of the equipment. Use enough

reflective and non-reflective material so that there are no

unmarked gaps of more than 6 ft. 2) Visible to the front:

Two yellow reflectors as close as possible to the right and

left extremes of the equipment.

4) The

attached equipment is in front of the tractor.

Special lighting requirements —None.

Special marking requirements — 1) Visible to the rear:

Red retroreflective material and non-reflective red-orange

fluorescent material. The retroreflective material should

mark the left and right extremes of the equipment. Use enough

reflective and non-reflective material so that there are no

unmarked gaps of more than 6 ft. 2) Visible to the front:

Two yellow reflectors as close as possible to the right and

left extremes of the equipment.

5) The

towed equipment extends more than 4 ft behind the hitch point

on the tractor.

Special lighting requirements — Covered above under "If

Tractor Illumination Is Obscured."

Special marking requirements — This equipment requires

an SMV emblem of its own, visible to the rear.

6) The

towed equipment extends more than 16 ft behind the hitch point

on the tractor.

Special lighting requirements — Covered above under "If

Tractor Illumination Is Obscured."

Special marking requirements — This equipment requires

an SMV emblem of its own, visible to the rear. In addition,

the sides of the equipment should be marked with amber or

yellow reflectors, spaced every 16 ft maximum. A reflector

should be placed as far to the rear on each side as possible.

7) The

towed equipment extends more than 25 ft behind the hitch point

on the tractor.

Special lighting requirements — This equipment should

have its own set of taillights, warning lights and turn indicators

as described above.

C.

Loading and Towing

1. Towing Equipment

2.

Front-End Loaders

Front-end loaders can make tractors unstable and subject to

side overturns.

3.

Loading and Unloading Tractors

When loading a tractor onto a trailer or truck, always load

it on level, stable ground. Make sure that the truck or trailer

cannot move by setting the brakes or blocking the wheels or

both. Whenever possible, slowly back the tractor onto the

truck or trailer. Check to see if anyone is behind the tractor

or near the trailer during loading.

IV. Miscellaneous

Topics

A. Other Tips for Maneuvering

B.

Hazards of Filling Gas Cans

Vehicle fires sometimes occur while people are filling metal

gas cans placed on plastic surfaces. This type of fire usually

involves a gas can in the back of a pick-up truck with a plastic

bed liner.

Gasoline tends to carry a static electric charge. When pouring

gasoline into a can, this charge can build up on the can.

If the can is sitting on concrete or on the ground, the static

charge can safely flow away. But when the can is sitting on

plastic, such as the plastic bed liner in a truck, the static

charge can not escape because the plastic is an insulator,

that is, it does not conduct electricity. A spark can occur

between the can and the fuel nozzle and ignite the gasoline.

When the spark occurs in the flammable range in the gasoline

vapor space near the open mouth of the gas can, a fire occurs.

Use only

gas cans approved by OSHA and follow these precautions.

C.

Steep Slopes

Sometimes a tractor must be operated on a steep slope.

D.

What to Do When the Tractor Gets Stuck

Getting stuck is not only embarrassing, but it can also be

dangerous.

E.

Used Equipment

The condition of equipment sold at auctions or transferred

from person to person varies widely, so it's important to

examine used equipment carefully.

When

equipment is purchased through a dealership, the purchase

usually includes a warranty, directions for maintenance and

operation, warning, "seals of approval" and assurances

that the equipment conforms with voluntary or federal standards.

Regardless of where equipment is bought, look for items that

may detract from safety, such as missing shields and poor

upkeep.

A bargain price may not be worth the risks involved. Don't

be blinded by a "sale" and end up with below-standard

equipment.

Consider

the following questions when buying used equipment.

F.

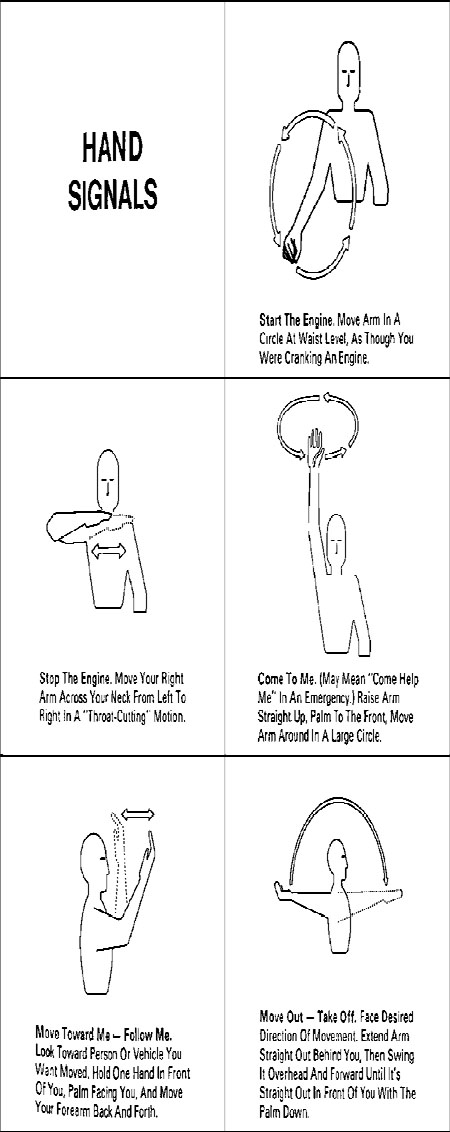

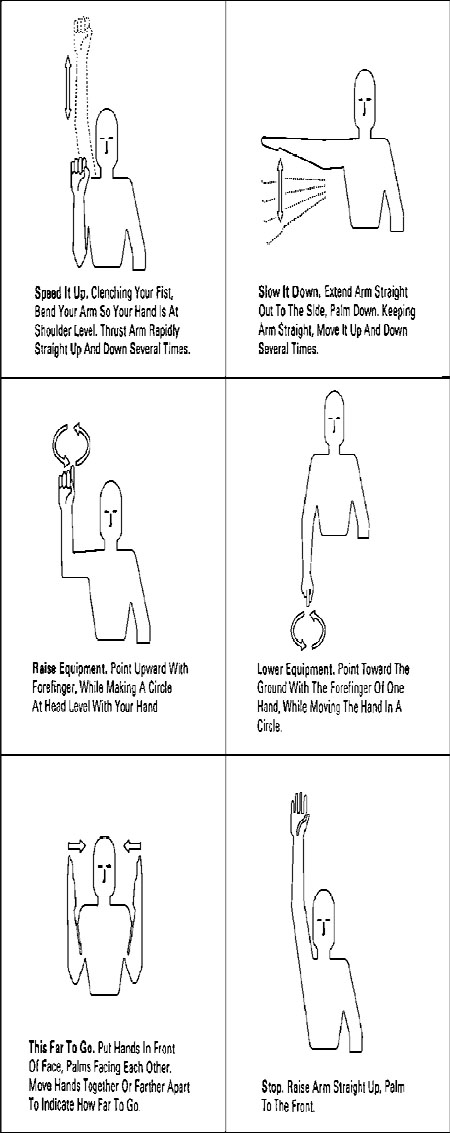

Hand Signals

Hand signals have been developed to provide a uniform means

of communication between workers on the ground and equipment

operators. They are especially useful when noise, distance,

or language barriers make voice communication difficult.

There are eleven recognized hand signals found in ASAE Standard

S351. They are illustrated in figures on the next page of

this publication.

1) Come to me.

2) Move toward me.

3 ) Move out.

4) Start the engine.

5) Stop the engine.

6) This far to go.

7) Stop.

8) Speed up.

9) Slow down.

10)Lower equipment.

11) Raise equipment.

Hand Signals for Communicating with Machinery Operators (part 2).

G.

Handling Large Hay Bales

When moving large bales, remember: Low and Slow. Avoid sudden

movements and turns which can easily cause the tractor to

overturn. The higher the loader is raised, the higher the

center of gravity, and the easier the tractor will overturn.

Only use equipment, such as a grapple hook or bale spike,

that is designed to be used with your tractor model for bale

transport.

Placing a bale in a regular tractor bucket and anchoring with

a chain is not adequate. Bales, especially if wet and thus

very heavy, can snap the chain. The bale then rolls down the

loader arms and crushes the operator. If the bale remains

on the tractor, it may catch fire from exposure to hot engine

components. The trapped operator will then be burned.

V.

Tractor Operator Checklist

An operator checklist is provided at the end of this publication

(see Table 5). This checklist is designed so that it can be

kept as a record of a tractor operator's training.

Safe and competent tractor operators are important to agriculture.

Incidents that cause injury and death and damage tractors,

equipment or crops are costly.

Many tractor incidents can be prevented by putting safer drivers

on safer tractors in a safer environment. Safer tractor operations

should be the goal of owners, managers, supervisors, and tractor

operators.

The following is a requirement for all agribusinesses that

fall under the jurisdiction of the Occupational Safety and

Health Act (OSHA).

Completion

of this checklist when tractor operators are first assigned

to a tractor and annually thereafter is evidence that employees

have been instructed in the safe use of the tractor.

The checklist can be used as is, or it may be modified to

better meet your specific needs. If a service mechanic is

responsible for some of the maintenance functions, you might

not need them listed on a checklist for your tractor operators.

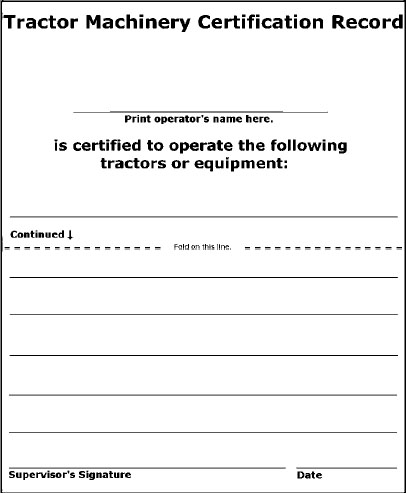

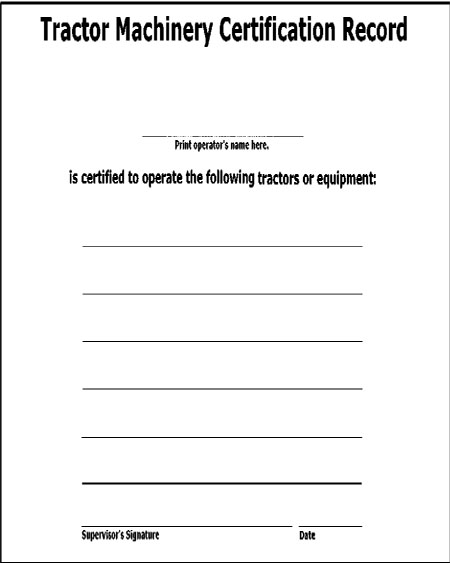

Included at the end of this publication are certificates which

can be used to document operator completion of checklist training.

The larger form is intended for employer files. The smaller

form can be carried by the employee; it is designed to fold

in half and fit in a wallet.

VI. Formula

for a Successful Tractor Rodeo

A tractor rodeo is a great way to communicate the importance

of safety and to provide specific safety information. The

event encourages operators to do the right thing the right

way, as well as provides a situation in which they can interact

positively with instructors and with each other.

What

exactly is a tractor rodeo'?

In a tractor rodeo, participants perform common equipment

operations, such as driving tractors or hooking and unhooking

equipment. The driving is usually done on a course laid out

by the instructors.

The course tests employees' precision, safety awareness, and

attention to detail. Likewise, handling equipment will be

a test of accurate execution of a task. (There should not

be a time element, since needless rushing to accomplish tasks

is the source many injuries.) A score sheet is used by judges

to assess the performance of each participant.

The rodeo can last through a morning or afternoon, or it can

be an all-day affair and include lunch and an awards ceremony.

In addition to the activities, safety information can be built

into the introductions, announcements, and event publications

so that it is clear that safety is the bottom line of the

day's activities. A special award for the safest driver is

a good idea, in addition to best overall and best various

categories.

Participants can compete individually or as teams, perhaps

based on their group affiliations.

Example

of a Successful Tractor Rodeo

The following examples are taken from materials developed

over 20 years of conducting tractor rodeos by Extension offices

in Lake County and Orange County, Florida.

The Schedule

The Lake-Orange County Tractor Rodeo is an all-day event starting

at 8 in the morning and ending around 3:30 in the afternoon.

The schedule emphasizes education in the morning; the rodeo

takes place after lunch. Titles for morning sessions are suggestions

only; use safety topics tailored for the group. Examples include:

sun, heat stress, chain saws, power tools, food safety in

the field, tractor safety, and chemical safety.

Here

is a sample program:

8:00-8:30 am — Registration and Announcements

8:30-9:00 am — Personal Safety

9:00-9:30 am — Pesticide Safety

9:30-10:00 am — Defensive Driving

10:00-10:30 am — Break

10:30-11:00 am— Safer Tractor Operation

11:00-11:30 am— Be Careful, Hazardous Materials

11:30-12:00pm — What's for Lunch? (Food Safety in the

Field)

12:00-1:00 pm— Lunch

1:00-3:00 pm— Rodeo

3:00-3:30 pm — Awards Presentation

The

Events

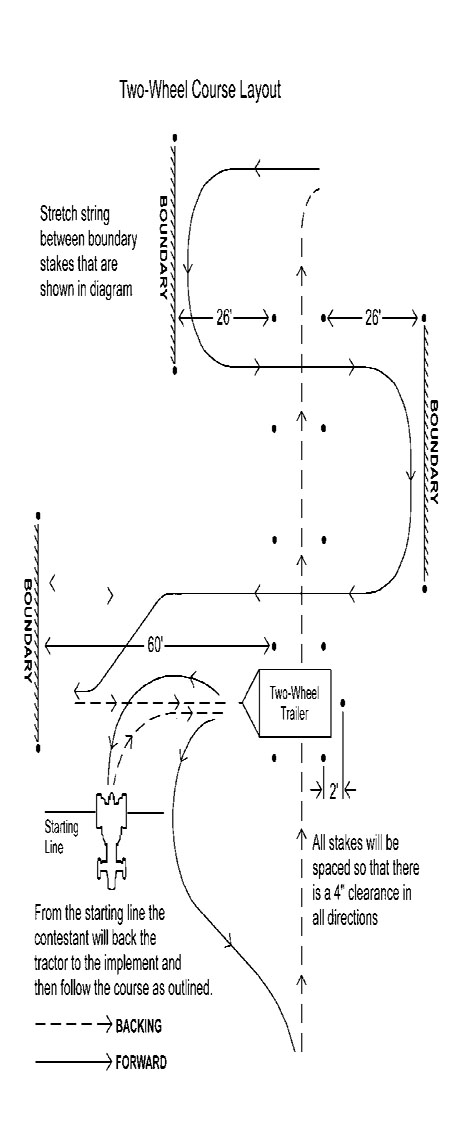

The Lake-Orange County rodeo includes three events. Individuals

compete in only one event, but organizations have one representative

in each event. All events can be combined in one course, such

as the one shown on the following page.

The events are:

Event #1: Backing — A trailer must be backed into

a stall. Once the tractor is in reverse, it must stay in reverse.

The stall is an area marked out with cones on the course for

the participant to back the trailer into.

Event #2: Hooking Up— Back a supply truck up to

a speed sprayer. Each contestant has to back blind to hook

up (that is, contestants can not leave the tractor seat during

the hook up operation).

Event #3: Driving Course — A course must be traveled

at constant speed without knocking down the cones."

Example Course for Tractor Rodeo

The

Scorecard

Judges for the Lake-Orange County rodeo use a scorecard to

evaluate the participants' performance. A perfect score is

zero, meaning that points are scored for omissions or errors.

Participants are scored in five areas: Pre-Warm-Up Preparation,

Engine Starting, Warm-Up and Clutch Operation, Driving, and

Safety. A sample scorecard is provided at the end of this

publication (see Table 6).

VII.

How Much Do You Know? Pre-Post Test on Tractor Safety

Testing operators before and after presenting the information

in this publication can make their learning efforts more successful.

You can use the sample Pre-Post Test as it is, or you may

wish to make up your own custom test which covers a specific

area in detail or to provide new questions.

We recommend that your Pre-Post Test include no more than

ten or fifteen questions.

Sample

Pre-Post Test

A copy of the sample test without the answer key can be found

at the end of this publication in Table 7.

1.Most injuries to tractor operators are preventable. True

or False.

2.The safety features on modern tractors can protect the operator

from anything. True or False.

3.Shortcuts usually save very little time while increasing

danger to the operator. True or False.

4. A ROPS will prevent a tractor overturn. True or False.

5.How often should oil, fuel, and other fluid levels be checked?

6.Discomfort is:

10.The

faster you are driving the less likely you are to jackknife.

True or False.

Answers — 1. True; 2. False; 3. True; 4. False; 5. Daily;

6. B; 7. Fall off tractor and are run over; 8. B; 9. C; 10.

False.

Additional

Pre-Post Test Questions

1.Loose clothing is a special danger near a PTO. True or False.

(True)

2.Agriculture-related injuries are often made worse because

injured workers in isolated areas may have to wait a long

time for help. True or False. (True)

3.A seat belt will hold you in the "zone of protection"

provided by a ROPS. True or False. (True)

4.Seat belts are not needed for short drives. True or False.

(False)

5.Over half of agricultural fatalities result from operating

what device? (Tractors)

6.Most injuries to tractor operators are preventable. True

or False. (True)

7.It is better to think about safety: A) before an incident,

B) after an incident. (A)

8.What are the three major elements to consider in developing

safer tractor operations? (The environment, the tractor, and

the tractor operator)

9.When we can not control the environment, greater safety

results from modifying our____? (Operations)

10.The safety features on modern tractors can protect the

operator from anything. True or False. (False)

11.What is the recommended minimum distance from an embankment

to operate machinery? (A distance equal to the depth of the

embankment is the minimum recommended distance.)

12.Wet or sandy soil makes an embankment more dangerous. True

or False. (True)

13.What does ROPS stand for? (Roll-over protective structure)

14. A ROPS will prevent a tractor overturn. True or False.

(False)

15.Increased tractor power makes what dangers more likely?

(Rear overturns, side overturns, loss of control)

16.Always wear a seat belt when operating a tractor equipped

with a ROPS. True or False. (True)

17.Wide wheel adjustments make a tractor safer to operate.

True or False. (True)

18.Never check for a hydraulic leak with what? (Your hand)

19.Shortcuts usually save very little time while increasing

danger to the operator. True or False. (True)

20.When possible, making one operator responsible for a tractor

is the best system. True or False. (True)

21.What is the minimum age at which employees may operate

a tractor? (16)

22.When a tractor is not in use, any hydraulic equipment attached

to it should be in what position? (Lowered)

23.What symptom can indicate exposure to carbon monoxide?

(Headache)

24.Supervisors have the responsibility of seeing that all

tractor operators have a complete understanding of all instructions

and rules. True or False. (True)

25.Small rewards -- such as a meal, a local merchant gift

certificate, or cash bonus -- presented monthly, can be effective

in promoting safety. True or False. (True)

26.Slow-moving

vehicle emblems are to be used for equipment traveling less

than ___ mph. (25)

27.How often should you check oil, fuel, and other fluid levels?

(Daily)

28.How often should you check for any oil, fuel or fluid leaks?

(Daily)

29.How often should you check tire condition and inflation

levels? (Daily)

30.How often should you check that platforms and steps are

clean and free of debris and tools? (Daily)

31.How often should you check to see that lights, brakes and

the steering mechanism are working properly? (Daily)

32.How often should you check that all gauges are giving proper

readings and that the engine, transmission, and hydraulic

system aren't making any unusual sounds? (Daily)

33.How can you determine what special pre-operation checks

a tractor might require? (Review the maintenance manual for

the tractor.)

34.When you're angry, you should not operate a tractor. True

or False. (True)

35.List personal protective equipment that might be needed

when operating a tractor. (Respirator, eye and ear protection,

protective clothing, head gear, gloves and boots)

36.Smoking is dangerous around what materials? (Gasoline or

other fuels, as when fueling the tractor; dry materials; or

pesticides)

37.Discomfort is: A) A normal part of work which keeps the

operator alert and makes him work harder, or B) Something

that tires and distracts the operator and can make work less

safe. (B)

38.When you are exhausted, you should: A) Push through to

get the job done, or B) Stop working until you are rested.

(B)

39.Impatience

promotes: A) Productivity, or B) Dangerous work habits. (B)

40.Dangerous work habits can result in injury to more than

the operator. True or False. (True)

41.The few extra seconds taken to do a job safely are: A)

more or B) less than the time taken to recover from an injury.

(B)

42.Extra riders on tractors are often injured in what way?

(They fall off tractor and are run over.)

43.If you've done something many times without incident, it

must not be dangerous. True or False. (False)

44.A ROPS makes a tractor safer for an extra rider. True or

False. (False)

45.It is easier to fall out of an enclosed cab than most people

think. True or False. (True)

46.What is the stopping distance for a tractor going 10 miles

per hour, under ideal conditions? (30 ft.)

47.Tradition is the best guide to safe practice. True or False.

(False)

48.According to the National Safety Council, what percentage

of tractor-related deaths occur on public roads? (1/3)

49.What time of day is best for moving tractors and equipment

on public roads: a) daytime, when visibility is good, or b)

nighttime when traffic is likely to be less. (A)

50.Correct marking and lighting of tractors and other farm

equipment are very important when these vehicles must operate

on public roads. What is the most basic required marking device

required for public road travel? (SMV or Slow-moving vehicle

emblem)

51.What marking device is recommended for application to all

sides of equipment for public road travel? (Reflective tape)

52.At what level should warning lights be placed on tractors

and other equipment for operation on public roads? (Eye level

of motorists)

53.Tractor

brakes are capable of stopping a tractor under all circumstances?

True or False (False)

54.Name a common road condition where traveling in a low gear

makes braking more effective? (Traveling up or down hills)

55.An escort vehicle may be required by law if a tractor together

with any towed equipment is excessively A) wide, B) Long C)

High D) Any of the above. (D)

56.In Florida, State law specifies what vehicles may be used

as escorts. True or False. (True)

57.What simple precaution can make lighting on tractors and

equipment more effective? (Cleaning)

58.A motorist may try to pass your tractor just when you are

preparing to turn left. What action on your part might encourage

a motorist to make this mistake? (Swinging to the right to

make a wide left turn)

59.How can the classic "Left-turn collision" scenario

be avoided? (Installation of extension mirrors and using turn

signals)

60.The majority of tractor-automobile collisions occur: A)

during wet weather, B) at night, C) on dry days in broad daylight.

(C)

61.As a rule of thumb, what is the maximum weight a tractor

may tow? (Up to 4.5 times its own weight)

62.Towed loads which are hitched above a tractor's drawbar

can cause what kind of incident? (Rear overturn)

63.Front-end loaders can make tractors unstable and subject

to what kind of incident? (Side overturns)

64.Filling a metal gas can with gasoline increases the static

electricity on the can. True or False. (True)

65.The static electricity that builds up on a metal can when

it is being filled with gasoline can cause dangerous sparking

if the can is sitting on an insulating surface, such as a

plastic bed liner. True or False. (True)

66. Long

hair is a special danger near a PTO. True or False. (True)

67.The small turning radius of a tractor makes jackknifing

more likely. True or False. (True)

68.The faster you are driving the less likely you are to jackknife.

True or False. (False)

69.It is generally safer for tractor/ towed equipment combos

to drive on the shoulder as much as possible. True or False.

(False)

70.Driving your tractor/towed equipment combination on the

road shoulder can cause unexpected hazards. True or False.

(True)

71.To let a line of cars pass you should: A) simply wave them

around, B) pull over into the shoulder and keep moving) or

C) pull over and stop. (C)

72.Any metal container is safe for carrying gasoline. True

or False. (False)

73.You should always take a second to secure a gasoline container

when transporting it. True or False (True)

74.Always keep the nozzle of a gasoline hose in contact with

the can while filling. True or False. (True)

75.Using a latch-open device to fill a portable gasoline container

can lead to very dangerous spills. True or False. (True)

76.A tractor is more stable on a slope when the front wheels

are A) upslope or B) downslope from the rear wheels. (Downslope)

77.Driving up a slope in a tractor makes what incident more

likely? (Rear overturn)

78.If you sense that the tractor you are operating is becoming

unstable, turn the front wheels downhill. True or False. (True)

79.If

your tractor gets stuck, what is the first tactic you should

try in an effort to get out? (Backing up)

80.Backing up when your tractor is stuck can prevent what

incident? (Rear overturn)

81.If backing out a stuck tractor doesn't work, what's the

next thing to try? (Tow it out using a front hitch)

82.When pulling a stuck tractor using a rear hitch, to what

device on the tractor should you connect? (Drawbar)

83.When towing use only steel cable or chain. True or False.

(True)

84.Nylon tow ropes have been known to break when in use, snap

back, and kill the tractor operator. True or False. (True)

85.When pulling out stuck equipment, whose job is riskier:

A) The operator of the stuck equipment or B) the operator

of the tow vehicle? (B)

86.When purchasing used equipment, you usually "get what

you pay for"? True or False. (True)

87.Used equipment can literally cost you an arm or a leg because

it may lack customary shields and guards. True or False. (True)

88.A tractor cab helps protect the operator from lightning

hazards. True or False. (True)

89.It's safe to assume that a tractor operator can operate

any kind of tractor. True or False. (False)

90.It's a good idea to re-certify tractor driver's how often?

(Annually)

91.An enclosed cab offers adequate protection for extra riders.

True or False. (False)

92.Only children as extra riders are a problem because adults

can protect themselves on a tractor. True or False. (False)

93.The following types of farm equipment are unsafe for extra

riders. (Check all that apply.) A) tractor, B) all-terrain

vehicle, C) pick-up truck cab, D) combine. (B; also A and

D if they are not equipped with a manufacturer-installed extra

seat.)

VIII. Resources

For more information about these and many other safety topics,

contact your county Extension office, or visit the Florida

AgSafe Network Web site:

http://www.flagsafe.ufl.edu

"Tractor Fundamentals: Best Practices," North American

Guidelines for Children's Agricultural Tasks. For more information,

contact the National Children's Center for Rural and Agricultural

Health and Safety. Web site: <http://www.nagcat.org>.

"Hand Signals for Agriculture," ASAE Standard S351.

"Operator Controls on Agricultural Equipment," ASAE

Standard S335.4.

"Roll-Over Protective Structures (ROPS) for Wheeled Agricultural

Tractors," ASAE Standard S383.1.

"Symbols for Operator Controls on Agricultural Equipment,"

ASAE Standard S304.5.

"Roll-Over

Protective Structures (ROPS)," Occupational Safety and

Health Administration, OSHA Standard 1928.51

"No Riders" decals may be purchased from the Farm

Safety 4 Just Kids organization. Call (515) 758-2827.

The following publications are available at your county Extension

office and at the EDIS Web site, <http://edis.ifas.ufl.edu>.

(IFAS Publication Numbers are in parentheses after the titles,

followed by the Web address to access the publication.)

Operator

Certification for the Employee.

Operator Certification for Employer Records.

Table

1. Is a few seconds worth the risk?

| If your risky shortcut saves: | You save this much time for 100 repetitions: | While multiplying your risk of injury by 100! |

| 3 seconds | 5 minutes | |

| 5 seconds | 10 minutes | |

| 10 seconds | 17 minutes |

Table

2. Isn't your safety worth a few extra seconds?

| Task

|

Time Invested |

100 Repetitions |

| Walking down steps instead of jumping off tractor | 7 seconds | 12 minutes |

| Walking around the PTO instead of stepping over it | 2 seconds | 3 1/3 minutes |

| Engaging

cylinder locks on combine when working near or under header |

30 seconds | 50 minutes |

| Getting

off mower to pick up something instead of leaning over

to pick it up as you drive by |

20 seconds | 33 minutes |

| Remember: The time you invest in performing a task safely is minimal when you compare it to the high financial and emotional costs associated with death, injury and permanent disability. | ||

Table

3. A tractor cannot stop before running over a thrown

rider, no matter how slowly it is going.

|

Tractor

speed (miles per hour)

|

Stopping

distance (feet)

|

How

far tractor travels until the average person reacts

(feet)

|

|

2

|

6

|

1.5

|

|

5

|

12

|

3.7

|

|

10

|

30

|

7.3

|

|

15

|

44

|

11.0

|

|

20

|

64

|

14.3

|

Table

4. Size limits beyond which escort vehicles are required

| State | Width | Length | Height | Overhang | Special |

| Alabama

|

12 ft | 75 ft | 16 ft | Rear:

5 ft Front: 10 ft |

Blade or bucket extends beyond the side of the vehicle |

| Florida

|

12 ft | 95 ft | 14

ft 6 in |

none stated | none stated |

| Mississippi | 12 ft | 99 ft | none | Rear:15 ft | none stated |

| Information obtained from Department of Transportation Permits Division in each of the respective states. | |||||

Table

5. Tractor Operator Checklist

| Tractor

Operator Checklist Directions: This checklist is designed to evaluate a tractor operator's abilities to safely maintain and operate a tractor. Mark (x) in the Yes column if the operator can perform the activity, or in the No column if the operator can not perform the activity. Mark the Not Applicable, NA, column if the activity is not appropriate for this tractor or operation. Make of Tractor __________________________ Model ___________________ |

|||

| Activity or Condition | Yes | No | NA |

| Personal Safety Precaution | |||

| Only operate the tractor if you are physically and mentally alert. | |||

| Wear close-fitting clothes and proper shoes. | |||

| Eat and drink in moderation, and do not operate the tractor if you have been drinking alcohol or taking drugs or medication. | |||

| Use basic hand signals. | |||

| Preparing the Tractor and Equipment for Safer Operation | |||

| Don't operate the tractor in closed buildings. | |||

| Check the location and condition of the fire extinguisher. | |||

| Check the location and condition of the first aid kit. | |||

| Read and understand decals on the tractor. | |||

| Make sure that the shield for the PTO and other parts are in place. | |||

| Keep steps and platform free of dirt, grease, and debris. | |||

| Check if the slow-moving vehicle emblem is in place, clean, and not faded. | |||

| Test lights to be sure they're working. | |||

| Check for loose tools and parts. | |||

| Clean the windows. | |||

| Read and understand all controls. | |||

| Check the condition and pressure of all tires. | |||

| Check oil level; add oil as needed. | |||

| Check coolant level; add coolant as needed. Do not remove radiator cap when hot. | |||

| Check the battery's electrolyte level and add battery water as needed. Don't use matches around the battery and don't smoke. | |||

| Check, clean, coat and tighten battery connections. | |||

| Locate all grease fittings and clean and lubricate them. | |||

| Refuel the tractor, making sure that the engine is cool and refrain from smoking. | |||

| Adjust wheel width. | |||

| Add or remove weights. | |||

| Check if equipment has been properly serviced and adjusted. | |||

| Starting, Operating, Stopping Tractor and Equipment | |||

| Make sure that the area is clear of people, pets and obstacles. | |||

| Adjust seat for comfort. | |||

| Start the tractor. | |||

| Check gauges for proper readings. | |||

| Listen for unusual sounds and shut off the engine if you hear any. | |||

| Check brakes. | |||

| Warm engine before applying a heavy load. | |||

| Never operate the tractor from the ground. | |||

| Raise, lower and extend the drawbar. | |||

| Clean and oil PTO shaft and splines. | |||

| Clean, connect and disconnect hydraulic lines. | |||

| Connect and disconnect electrical connections. | |||

| Check hydraulic controls for proper operation. | |||

| Engage PTO slowly; check for proper operation. | |||

| Operate equipment at proper forward speed. | |||

| Operate equipment at proper PTO speed. | |||

| Watch and listen to equipment; shut off power at the first sign of a malfunction. | |||

| Do not unclog, adjust, or service equipment while it is running. | |||

| Observe all traffic rules when traveling on the road. | |||

| Lock brakes together for high-speed travel. | |||

| Shift gears properly. | |||

| Watch for obstructions in the field. | |||

| Back slowly, and watch behind. | |||

| When stuck, back out or have the tractor towed. | |||

| Leave the tractor in a low gear going down hills. | |||

| Cool engine, then shut it off. | |||

| On the following lines, add additional specific checklist items important for your workplace. | |||

| Tractor

Operator Instructions 1. Securely fasten your seat belt if the tractor has a ROPS. 2. Where possible, avoid operating the tractor near ditches, embankments, and holes. 3. Reduce speed when turning, crossing slopes, and on rough, slick or muddy surfaces. 4. Stay off slopes too steep for safe operation. If necessary, back up a slope and drive forward going downhill. 5. Watch where you are going, especially at the end of rows, on roads, and around trees. 6. Do not permit extra riders. 7. Operate the tractor smoothly — no jerky turns, starts, or stops. 8. Hitch only to the drawbar and hitch points recommended by the manufacturer. 9. When the tractor is stopped, set brakes securely, and use park lock if available. |

|||

Tractor Machinery Certification Record ______________________________________________ (Employee's Name) is certified to operate the following tractors or equipment: _______________________________________________ _______________________________________________ _______________________________________________ _________ ____________________________________ Date Supervisor |

|||

Table

6. Score Sheet for Tractor Rodeo

|

|||||||||||||||||||||||||||||||||||||||||||||

Pre-Warm-Up

|

|||||||||||||||||||||||||||||||||||||||||||||

Starting

Engine

|

|||||||||||||||||||||||||||||||||||||||||||||

Warm-Up

and Clutch Operation

|

|||||||||||||||||||||||||||||||||||||||||||||

Driving

|

|||||||||||||||||||||||||||||||||||||||||||||

Safety

|

|||||||||||||||||||||||||||||||||||||||||||||

|

GRAND

TOTAL (TRACTOR OPERATIONS)______

|

|||||||||||||||||||||||||||||||||||||||||||||

Figuring

Final Score

GRAND TOTAL _____ |

Table

7. Tractor Safety Pre-Post Test

| Tractor

Safety Pre-Post Test Circle the correct answer or write it in the space provided. |

||

| 1. | Most injuries to tractor operators are preventable. | True or False. |

| 2. | The safety features on modern tractors can protect the operator from anything. | True or False. |

| 3. | Shortcuts usually save very little time while increasing danger to the operator. | True or False. |

| 4. | A ROPS will prevent a tractor overturn. | True or False. |

| 5. | How often should oil, fuel, and other fluid levels be checked? | |

| 6. | Discomfort

is: A) A normal part of work which keeps the operator alert and makes him work harder, or B) Something that tires and distracts the operator and can make work less safe. |

A B |

| 7. | Extra riders on tractors are often injured in what way? | |

| 8. | At